As Benoit has continued to invest and expand, our core competencies have broadened, bringing new customers to the Benoit family, and new opportunities to provide products and services. Our engineering department works in conjunction with technical sales to offer full-spectrum manufacturing services to OEMs and service companies. From components to finished goods, Benoit is proud to offer efficient and innovative print and turn-key manufacturing services to the oil and gas industry.

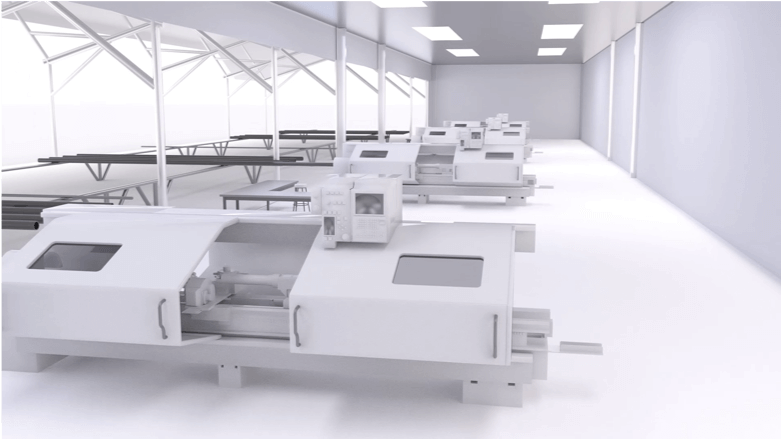

Machine Capabilities:

| 29 | Mazak M5 | 7 1/8″ spindle dia. | 144″ bed | 24″ swing |

| 3 | Mazak 450 | 7 1/8″ spindle dia. | 120″ bed | |

| 2 | Mazak Power Master | 14 3/4″ spindle dia. | 160″ bed | 34″ swing |

| 1 | Mazak VTC200C | 6″ spindle dia. | 72″ bed | 14″ chuck |

| 1 | Acra AM5AC | 4″ spindle dia. | 60″ bed | 12″ chuck |

| 1 | Kingston Manual | 4 1/16″ spindle dia. | 102″ bed | 30″ swing |

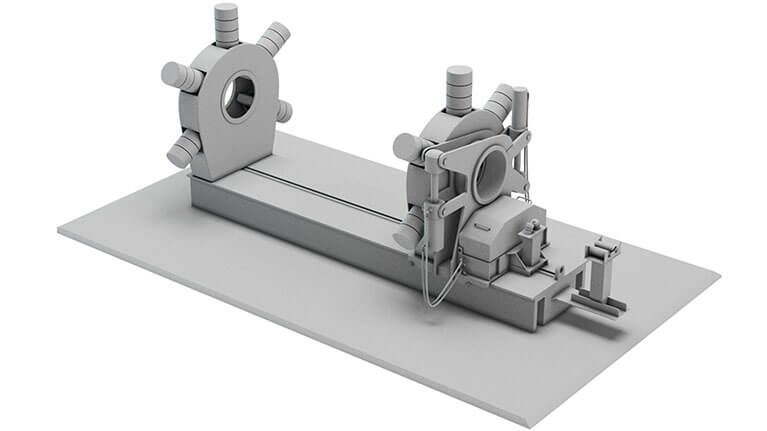

WATCH: A quick video to learn about the threading operation.

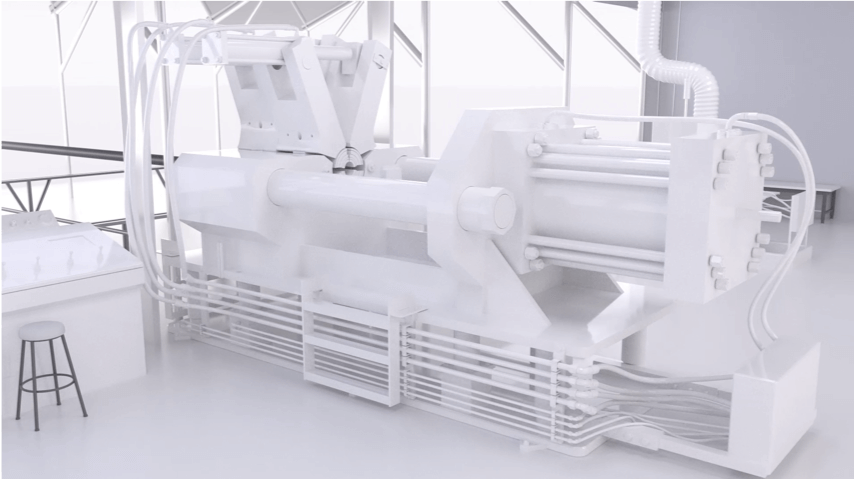

Torque-turn Assembly

Utilizing the latest hydraulic computer controlled torque units, Benoit provides customers a 20,000 sq.ft. indoor space to make up components into assemblies more than 100’ long and up to 22” ODs.

A climate controlled environment is made available to onsite engineers, consultants, and third-party inspectors. Live video feed of the shop floor and from inside the testing tanks is displayed on multiple TV monitors within the office to provide customers a comfortable and efficient workspace.

Technology & Quality Program

An ISO 9001:2015 registered and API certified company

Our customers rest assured knowing that Benoit operates under stringent controls and operating procedures to guarantee tolerances are held and ensure the continuous improvement of our processes, products and services.

In addition to our quality control inspectors on the manufacturing floor, Benoit inspects products using a state-of-the-art Coordinate Measuring Machine (CMM) with unlimited touch-points to ensure consistency and operational performance of our products. Benoit’s landing nipples are certified in accordance with API 14-L, and both landing nipples and sliding sleeves are 100% CMM inspected for dimensional verification. Benoit carries a number of threading licenses to better serve customers and meet the various requirements of their string design, including prominent connections such as JFE-BEAR, JFE-LION, and JFE-FOX.

WATCH: A quick video to learn about the cold swaging and expansion process.