BLANKING DIMENSIONS

Blanking Dimensions for Benoit Proprietary Connections

Please click below to access the blanking dimensions for Benoit’s family of proprietary connections. If you require any additional information, or would like to speak with a Benoit representative, please contact us ...

Please click below to access the blanking dimensions for Benoit’s family of proprietary connections. If you require any additional information, or would like to speak with a Benoit representative, please contact us ...

PROCEDURES

Flush & Semi-Flush Connection Running Procedures

For customers running BTS Flush & Semi-Flush connections, please follow the link below to Benoit’s recommended running procedures. Flush & Semi-Flush Connection Running Procedures ...BTS Running Procedures

For running procedures of the BTS connection, please check out the attached document and do not hesitate to give our technical sales team a call with any questions. BTS Running Procedures ...Private: Premium Connection Brochure

Benoit designs, tests, and manufactures premium connections for the upstream oil & gas industry. Please check out our Premium Connection Brochure to learn more about our connection offerings ...CERTIFICATES & LICENSES

An ISO 9001:2015 registered and API certified company,

Benoit prides itself on quality control and conformance.

Our customers rest assured knowing that Benoit operates under stringent controls and operating procedures to guarantee tolerances are held and ensure the continuous improvement of our processes, products and services.

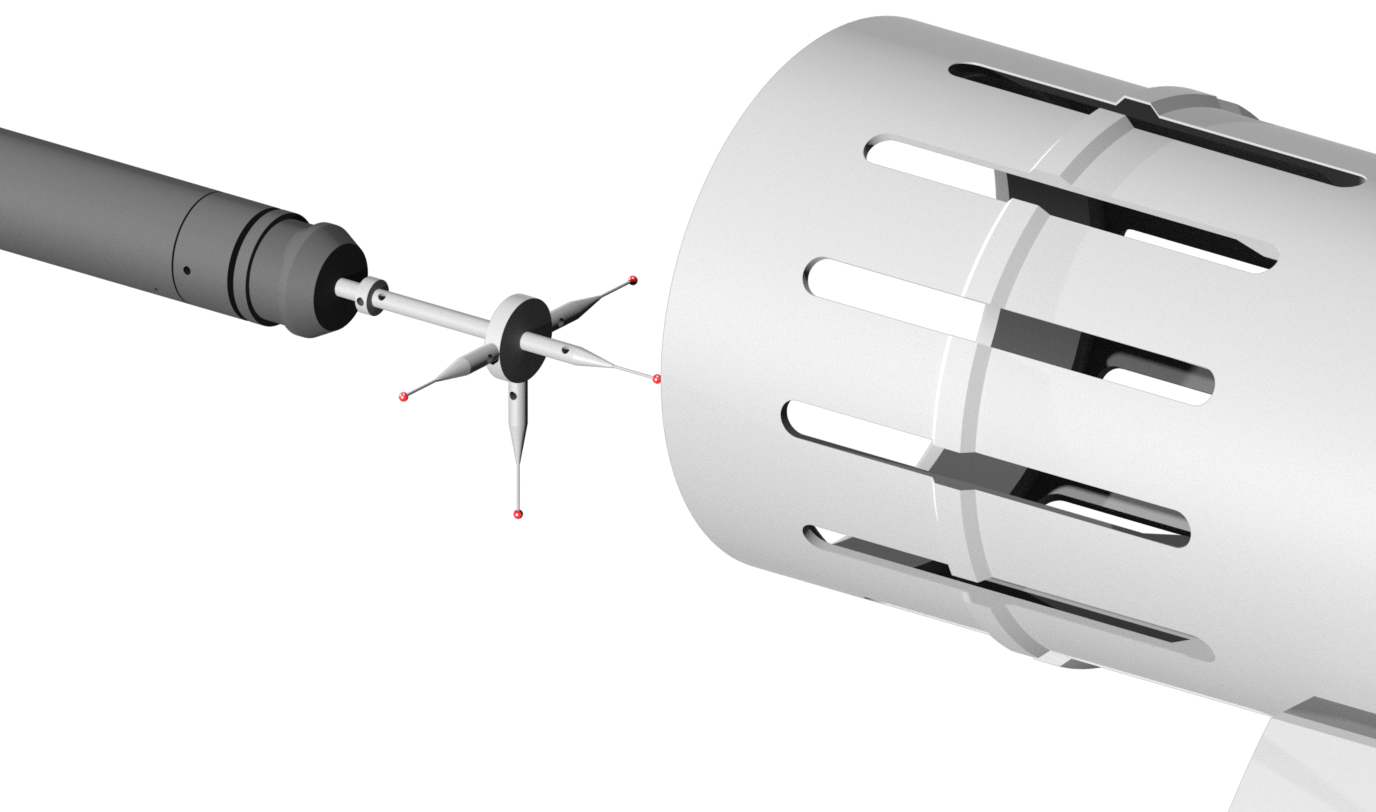

In addition to our quality control inspectors on the manufacturing floor, Benoit inspects products using a state-of-the-art Coordinate Measuring Machine (CMM) with unlimited touch-points to ensure consistency and operational performance of our products. Benoit’s landing nipples are certified in accordance with API 14-L, and both landing nipples and sliding sleeves are 100% CMM inspected for dimensional verification.

Benoit carries a number of threading licenses to better serve customers and meet the various requirements of their string design, including prominent connections such as JFE and TMK UP ULTRA™ Premium.