Project Coordinators work directly with engineers, service companies and third party reps to organize, schedule and track all aspects from manufacturing to shipping.

Our team provides industry renowned well and assembly schematics, technical data, 24/7 customer support, and they ensure thread consistency, bore drifts, O.D. & I.D. clearance for tools.

Our inventory of finished goods from seamless tubing to flow control accessories, and raw materials from J-55 to hyper chromes reduce delivery times and any associated manufacturing delays.

If your project requires a unique test or prep regime before shipping to the rig, our team of project coordinators has the experience, knowledge, and resources to pull from in order to complete the job. Let us handle the details, so you can focus on the next steps of your project.

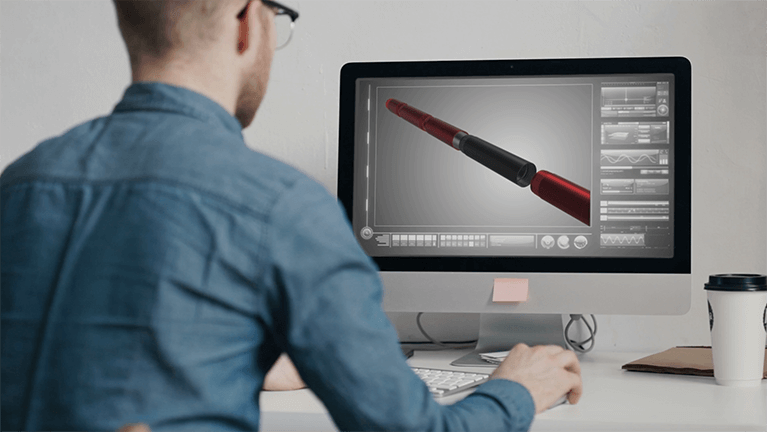

Product Design

Designed to meet the increasing demands of the oil and gas industry, our solutions are state-of-the-art, cover a breadth of applications, environments and real-world situations, and best-of-all are tailored to meet our customer’s needs.

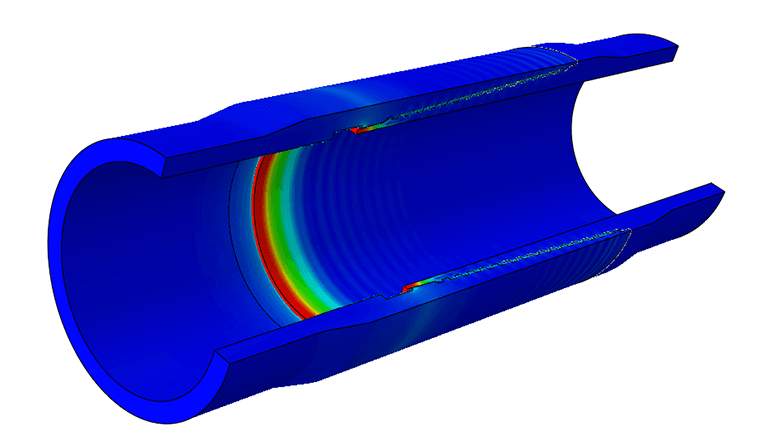

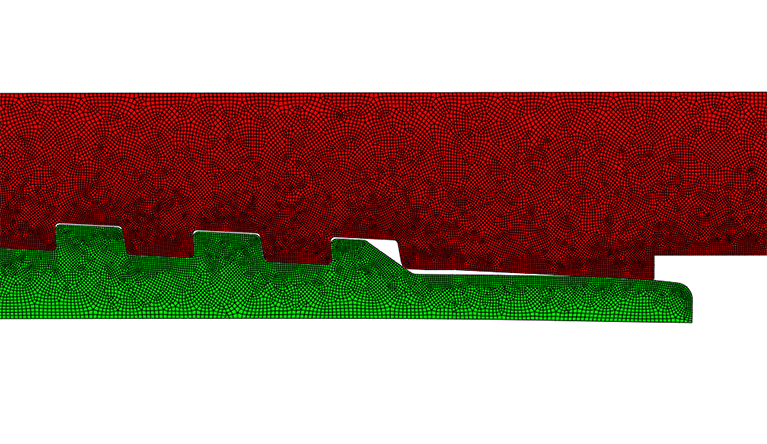

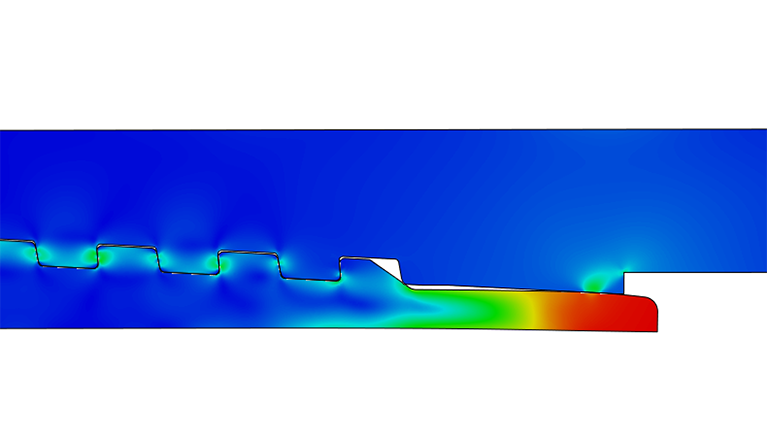

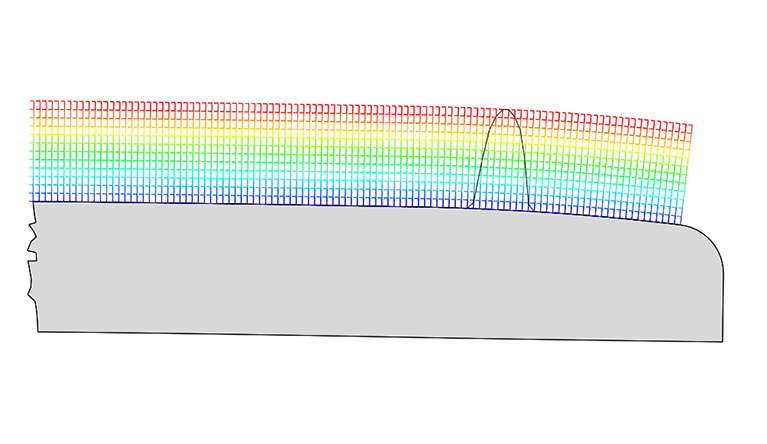

Benoit’s research and development team develop, design and implement new technologies to improve connection design and downhole tools. Finite Element Analysis (FEA) is performed in-house and we work closely with various third-party outfits to successfully validate designs per customer requirements.

This expertise, when coupled with our machining capacity and in-house testing capabilities, create a streamlined process for customers.

Performance Testing

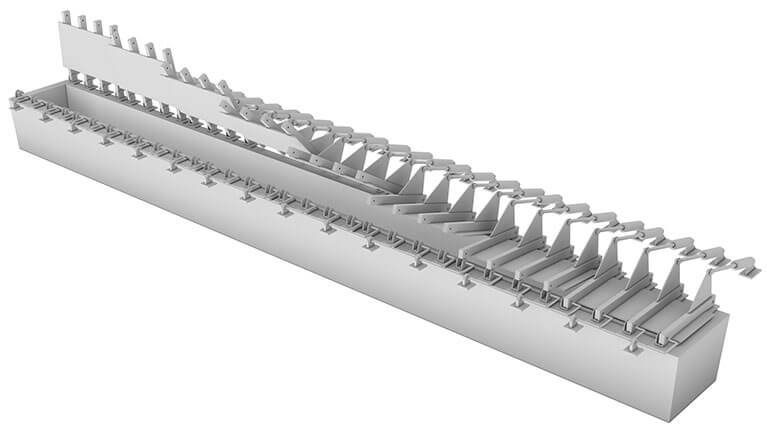

Benoit invested in 3 custom-designed testing enclosures (55’, 80’ and 110’ long) which were engineered to provide a safe workplace while conducting internal pressure testing of downhole assemblies.

In our torque-turn department, operators make up critical downhole components and test the assemblies to identify leaks or any faults in the equipment before running on the rig. Pressure testing is conducted using water or nitrogen-gas medium, up to 20,000 psi. We have live in-tank video monitoring and recording to properly identify pressure containment problems. Assembling and testing these assemblies onshore reduces costs by preventing rig downtime.